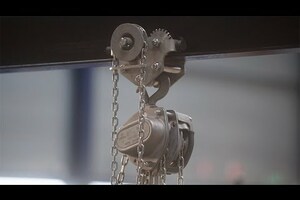

HD3C Spark Resistant Push/Pull Trolley

Spark-free lifting.

HD3C Spark Resistant Push/Pull Trolley

Spark-free lifting.

The reliability, operational smoothness, and safety of your hoist depends on the trolley. Contoured wheels that fit both tapered and flat-flange beams, lifetime lubricated bearings, and a low-turn radius are just some of the benefits of the HD3C spark resistant push/pull trolley.

Certified to ATEX standards to ensure safer lifting in dust-laden or explosive gas atmospheres.

Electric Galvanized Surface Treatment

Treated with a layer of zinc to protect the trolley from rusting or corrosion.

Strong, Lightweight, and Compact Design

Don’t be fooled by its small stature - what the HD3C lacks in size and weight, it more than makes up for in strength.

Bronze Coated Wheels

Bronze coated wheels specifically designed to resist sparks at the point of contact along the beam so you can safely move the load. Contoured to fit both tapered and flat flange beams.

HD3C Easy Adjustable Trolley

The reliability, operational smoothness, and safety of your hoist depends on the trolley. Contoured wheels that fit both tapered and flat-flange beams, lifetime lubricated bearings, and a low-turn radius are just some of the benefits of the HD3C spark resistant push/pull and geared trolley.

Certified to ATEX standards to ensure safer lifting in dust-laden or explosive gas atmospheres.

CAPACITY

- 1/2 to 30 Metric Tons (1/2t ~ 3t, larger sizes available up to 30 Metric Tons)

STANDARDS

- EC machinery directive 2006/42/EC

- ATEX Directive 2014/34/EU

- EN13157

- Equipment classification Gas ATEX Explosion Protected II 2G EX h IIC T4 Gb (zone 1)

- Equipment classification Dust ATEX Explosion Protected II 2D EX h IIIC T135°C Db (zone 21)

- Operating Conditions: -20 to +40° Celsius

OPTIONS

- Special surface protection according to ISO 12944

- Extended handwheel max. 3000mm, dimension “M”

- Parking device for parking in unloaded condition

- Special side plates to increase dimension “E”

- Stainless steel nameplate with tag number

- Straight suspension bolt with spacer

- 3.1 load test certificate

- 3.1 material certificate

- Solid bronze wheels

BODY

- A strong, lightweight, and compact design

- Electric galvanized up to 6t larger chassis are 2 layer paint system, RAL7021

- Rubber bumpers mounted on the trolley

- Safety lugs supplied standard

WHEELS

- Bronze coated wheels

- Contoured to fit both tapered and flat-flange beams

COMPATIBILITY

- Adjustable flange width to fit a wide variety of beam flange widths

BEARINGS

- Maintenance-free low friction design

- Lubricated for life

OPERATION

- Push trolley: Suited to applications involving greater traversing distances

Choose product configuration below to view info:

Push/Pull Trolley

Dimensions

| Capacity (tonnes) | Model | A | B | C | L | H | W | R | D | E | F | G |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | HD3C8380000600 | 45 | 60 | 15 | 150 | 125 | 160 | 75 | 52 | 15 | 45 | 30 |

| 1 | HD3C8380001101 | 60 | 75 | 18 | 190 | 160 | 175 | 99 | 60 | 20 | 60 | 30 |

| 2 | HD3C8380002200 | 80 | 100 | 22 | 255 | 205 | 215 | 123 | 75 | 27 | 80 | 35 |

| 3 | HD3C8380003300 | 100 | 120 | 25 | 300 | 245 | 250 | 144 | 90 | 35 | 100 | 40 |

* All measurements in millimeters (mm). Please confirm specifications with technical support before purchase.

Specifications

| Capacity (tonnes) | Model | Minimum Radius (mm) | Ship Weight (kg) | Flange Width (in) |

|---|---|---|---|---|

| 1/2 | HD3C8380000600 | 700 | 3 | 2.2 - 4 |

| 1 | HD3C8380001101 | 1050 | 5 | 2.2 - 4 |

| 2 | HD3C8380002200 | 1400 | 11 | 2.9 - 5 |

| 3 | HD3C8380003300 | 1750 | 18 | 3.5 - 5.6 |