VLLB Spark Resistant Lever Hoist

Spark-free lifting.

VLLB Spark Resistant Lever Hoist

Spark-free lifting.

Strength meets safety with Van Leusden's spark-resistant lever hoist: all the proven durability you know and love from Kito's lever hoists, now with added features to keep you safe in hazardous environments.

Certified to ATEX standards to ensure safer lifting in dust-laden or explosive gas atmospheres.

Nickel Plated Load Chain

Kito has successfully established a world-renowned reputation for manufacturing a lighter-weight, ultra-strong, high-performance load chain. What’s more, the VLLB Grade 100 chain uses a shorter and narrower link profile for greater surface area contact, which improves wear resistance and overall tensile strength.

FAILSAFE FREEWHEEL SYSTEM

Our widely acclaimed fail-safe freewheel system closes the gap between operator safety and load control. Developed in-house 30 years ago, the freewheel mechanism was intentionally created as a two-step process to eliminate the risk of accidental free chaining. The result is dramatically improved functionality and operator safety.

Bronze Coated Top & Bottom Hooks

Stay safe from top to bottom with load hooks designed to resist sparks at the point of contact.

ATEX Rated

The Spark Resistant Lever Hoist conforms to the European ATEX directive 2014/34/EU for certified use in potentially explosive atmospheres. ATEX is a multi-level technical standard mandatory in the European Economic Area (EEA) for using equipment in dust-laden or explosive environments.

CAPACITY

- 500 - 9,000 kg

STANDARDS

- ASME B30.21 Safety Standard

- ASME HST-3 Performance Standard

- At rated capacity, load-bearing parts are only stressed to 25% of their limit

- EC machinery directive 2006/42/EC

- ATEX Directive 2014/34/EU

- Equipment classification Gas ATEX Explosion Protected II 3G EX h IIB T3 Gc (zone 2)

- Equipment classification Dust ATEX Explosion Protected II 3G EX h IIIB T200°C Dc (zone 22)

- EN13157

- Overload limiter standard

OPTIONS

- Custom lift lengths to suit requirements

- Overload signal

BODY

- Rugged, high-impact stamped steel housing

- Compact and lightweight

- Open design for easy inspection and cleaning without dismantling the unit

- Surface treatment power coating, colour Munsell 6YR6/14R

HOOKS

- Bronze coated top and bottom hooks

- Top and bottom hooks are equipped with self-closing heavy duty hook latches

- Top and bottom hooks rotate 360 degrees

OPERATION

- 360-degree handle rotation

- Rubber grip handle for non-slip operation

- Operate in close quarters with 15-degree recovery stroke

- Patented spring-loaded freewheel mechanism for easy adjustment of the load chain and protection against accidental freewheeling under load

GEARS

- Highly durable, split-load double reduction gears

- Fine tooth precision gearing to reduce required force

- Induction heat-treated and case-hardened

- Enclosed to protect from dust and water

LOAD CHAIN

- Nickel plated as standard

- Grade 100 heat-treated

- Link Pitch: 2.8D

- Protective guard around the chain pin for enhanced safety

BRAKE

- Weston-style load brake with four braking surfaces, two brake pads and two brake pawls for added safety

- Five-star thread on brake ensures a level braking surface to ease load break-out

OPTIONAL OVERLOAD PROTECTION

- Slip Clutch: Engages during an excessive overload keeping the load stationary

Choose product configuration below to view info:

Hook Mount

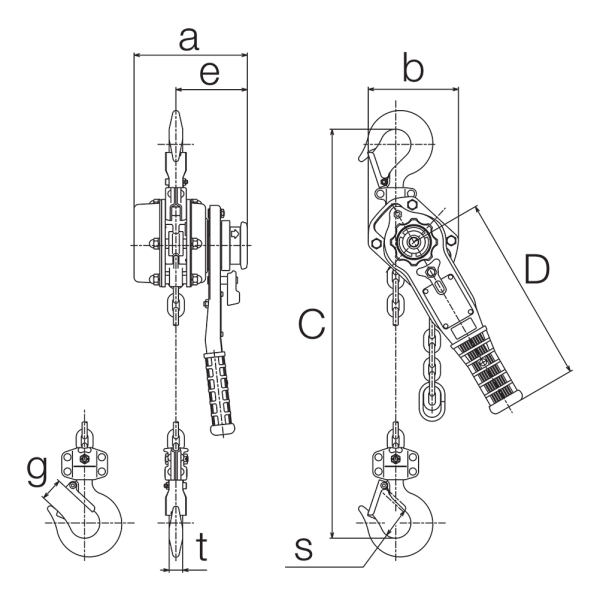

vllb line drawing

*For informational purposes only, contact Kito for dimensional drawing

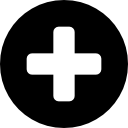

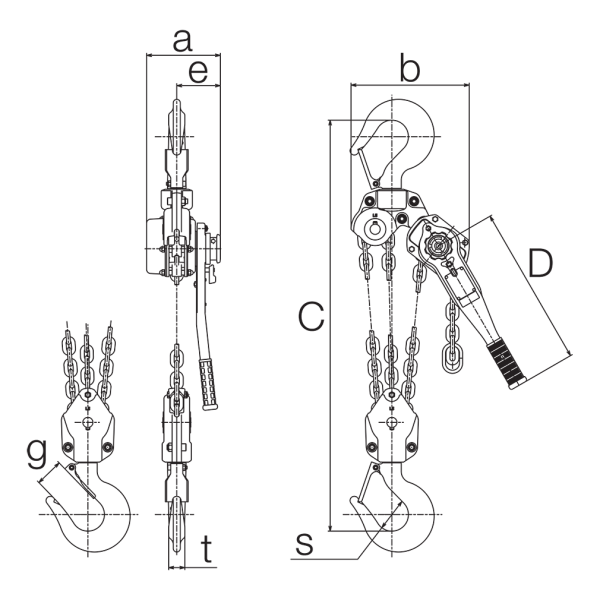

VLLB line drawing

*For informational purposes only, contact Kito for dimensional drawing

Dimensions

| Capacity (tonne) | Model | a | b | C | D | e | g | S | t |

|---|---|---|---|---|---|---|---|---|---|

| 500 kg | VLLB005 | 114 | 119 | 280 | 245 | 97 | 23.5 | 35.5 | 14 |

| 1,000 kg | VLLB010 | 114 | 119 | 300 | 245 | 97 | 29 | 42.5 | 15 |

| 1,600 kg | VLLB015 | 159 | 126 | 335 | 265 | 100 | 32 | 42.5 | 19 |

| 2,500 kg | VLLB025 | 173 | 150 | 375 | 265 | 102 | 36.5 | 47 | 21 |

| 3,200 kg | VLLB032 | 190 | 159 | 395 | 415 | 112 | 39 | 50 | 24.5 |

| 6,300 kg | VLLB063 | 190 | 217 | 540 | 415 | 112 | 50 | 60 | 34 |

| 9,000 kg | VLLB090 | 190 | 304 | 680 | 415 | 112 | 72.5 | 85 | 41.5 |

* All measurements in millimeters (mm). Please confirm specifications with technical support before purchase.

Specifications

| Capacity (tonne) | Model | Standard Lift (ft) | Headroom (in) | Load Chain Falls |

|---|---|---|---|---|

| 500 kg | VLLB005 | 5 | 11 | 1 |

| 1,000 kg | VLLB010 | 5 | 11.8 | 1 |

| 1,600 kg | VLLB015 | 5 | 13.1 | 1 |

| 2,500 kg | VLLB025 | 5 | 14.75 | 1 |

| 3,200 kg | VLLB032 | 5 | 15.5 | 1 |

| 6,300 kg | VLLB063 | 5 | 21.25 | 2 |

| 9,000 kg | VLLB090 | 5 | 26.77 | 3 |