MRQ Production Motorized Trolley

Smooth sailing from here on out.

MRQ Production Motorized Trolley

Smooth sailing from here on out.

Built for the EQ & SEQ Series VFD Hoist, the MRQ Motorized Trolley will double your work efficiency. As with its hoist counterpart, the MRQ is made with a Variable Frequency Drive for the smooth starts and stops and precise load control you've come to know and love.

Available in both single and three phase power.

Pull Rotor Brake

With no brake coil to fail or discs to replace, the electromagnetic pull rotor brake on the MRQ is self-adjusting and virtually maintenance-free.

Side Guide Rollers

Designed for very smooth travel along the beam, the MRQ motorized trolley uses an innovative side-guide roller system that keeps the load controlled and on track while traversing.

Variable Frequency Drive (VFD)

Comes with a standard “under-the-cover” variable frequency drive – regardless of voltage. This device works by varying the power to the motor, which allows you to adjust both the high and low speeds. It also provides a soft-start/soft-stop operation to reduce shock loads, swing, and bounce – resulting in more precise load control and longevity of the hoist.

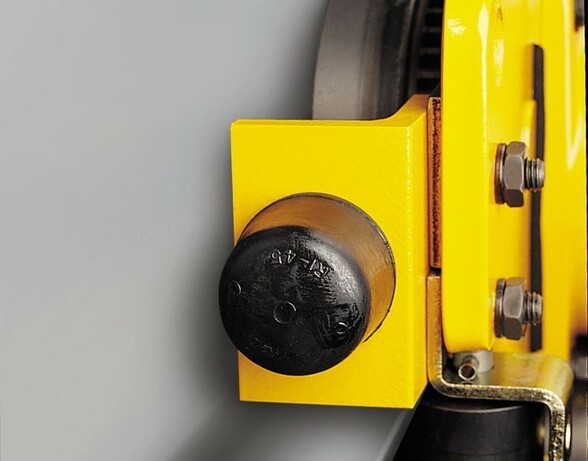

Rubber Bumpers & Drop Stops

Drop stops and rubber bumpers not only provide additional security for the operator, they also protect the equipment against collisions.

CAPACITY

- 1/8 to 1 metric tonnes

STANDARDS

- ASME H4

- ASME B30.16

- CSA C22.2 NO. 33, 14-13, 66.1-06

- IP55 dust-tight and watertight environmental protection

BODY

- Die-cast aluminum frame

- Completely sealed body

- Suitable for both indoor and outdoor applications

- Lightweight

- Low headroom profile

WHEELS

- Contoured wheels fit both tapered and flat-flange beams.

VFD

- Variable Frequency Drive

- Adjustable speeds

- Standard speed ratio 6:1 adjustable to 10:1

PUSH BUTTON STATION

- Impact resistant plastic with molded strain relief to avoid damage from pulling on the push button cord

- IP65 dust-tight and watertight environmental protection

- Ergonomic design – easy to use one-handed operation

- E-Stop

BEARINGS

- High quality anti-friction ball and roller design

BRAKE

- Durable, reliable, and maintenance free pull-rotor motor brake

MOTOR

- Single & Three phase option

OPERATING CONDITIONS

- -20˚ to +40˚C

- Humidity of 85% or less

OVERTRAVEL PROTECTION

- Rubber bumpers

- Drop stops

- Provides protection from collisions and is supplied standard

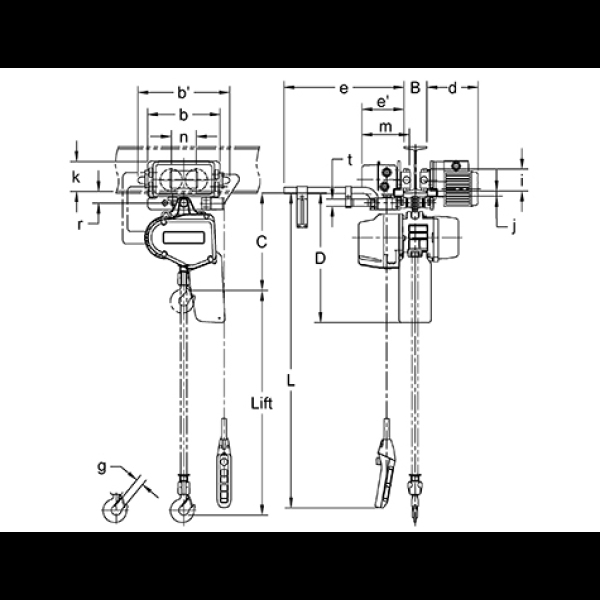

Dimensions

| Capacity (tonne) | Model | C (in.) | D | b' | b | d | e | e' | g | i | j | k | n | r | t |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/8 | SEQM001SD | 16.5 | 20.3 | 15.6 | 12.4 | 8.7 | 20.3 | 7.1 | 1.1 | 3.7 | 1.1 | 5.1 | 4.3 | 2.0 | 1.2 |

| 1/4 | SEQM003SD | 16.5 | 20.3 | 15.6 | 12.4 | 8.7 | 20.3 | 7.1 | 1.1 | 3.7 | 1.1 | 5.1 | 4.3 | 2.0 | 1.2 |

| 1/2 | SEQM005SD | 17.3 | 20.3 | 15.6 | 12.4 | 8.7 | 20.3 | 7.1 | 1.1 | 3.7 | 1.1 | 5.1 | 4.3 | 2.0 | 1.2 |

| 1 | SEQM010SD | 19.3 | 22.2 | 15.6 | 12.4 | 8.7 | 20.3 | 7.1 | 1.2 | 3.7 | 0.9 | 5.1 | 4.3 | 2.0 | 1.2 |

. Please confirm specifications with technical support before purchase.

Specifications

| Capacity (tonnes) | Model | Speed (ft/min) | Flange Width (in) | Minimum Radius for Curve (mm) | Motor H.P. | Ship Weight (lbs) | Weight Per Additional 5ft of Lift (lbs) | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Hoist Lifting | Trolley Traversing | Standard | Extension Shaft | Hoist | Trolley | |||||

| 1/8 | SEQM001SD | 56/9.3 | 80/13 | 2.28 - 6.02 | 6.02 - 12 | 800 | 0.67 | 0.54 | 139 | 2.4 |

| 1/4 | SEQM003SD | 33/5.5 | 80/13 | 2.28 - 6.03 | 6.03 - 12 | 800 | 0.67 | 0.54 | 141 | 2.4 |

| 1/2 | SEQM005SD | 25/4.2 | 80/13 | 2.28 - 6.04 | 6.04 - 12 | 800 | 1 | 0.54 | 146 | 2.4 |

| 1 | SEQM010SD | 17/3.9 | 80/13 | 2.28 - 6.05 | 6.05 - 12 | 800 | 1.3 | 0.54 | 165 | 3.85 |

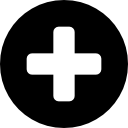

Dimensions

| Capacity (tonne) | Model | C (in.) | D | b' | b | d | e | e' | g | i | j | k | m | n | r | t |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/8 | EQM001SD | 16.5 | 20.3 | 15.6 | 12.4 | 8.7 | 20.3 | 7.1 | 1.1 | 3.7 | 1.1 | 5.1 | 8.1 | 4.3 | 2.0 | 1.22 |

| 1/4 | EQM003SD | 16.5 | 20.3 | 15.6 | 12.4 | 8.7 | 20.3 | 7.1 | 1.1 | 3.7 | 1.1 | 5.1 | 8.1 | 4.3 | 2.0 | 1.22 |

| 1/2 | EQM005SD | 17.3 | 20.3 | 15.6 | 12.4 | 8.7 | 20.3 | 7.1 | 1.1 | 3.7 | 1.1 | 5.1 | 8.1 | 4.3 | 2.0 | 1.22 |

| 1 | EQM010SD | 19.3 | 22.2 | 15.6 | 12.4 | 8.7 | 20.3 | 7.1 | 1.2 | 3.7 | 1.2 | 5.1 | 8.1 | 4.3 | 2.0 | 1.22 |

. Please confirm specifications with technical support before purchase.

Specifications

| Capacity (tonnes) | Model | Travel Speed (ft/min) | Flange Width (in) | Minimum Radius for Curve (mm) | Motor H.P. | Ship Weight (lbs) | Weight Per Additional 5ft of Lift (lbs) | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Hoist | Trolley | Standard | Extension Shaft | Hoist | Trolley | |||||

| 1/8 | EQM001SD | 59/6 | 80/13 | 2.28 - 6.02 | 6.02 - 12 | 800 | 0.67 | 0.54 | 139 | 2.4 |

| 1/4 | EQM003SD | 33/6 | 80/13 | 2.28 - 6.03 | 6.03 - 12 | 800 | 0.67 | 0.54 | 141 | 2.4 |

| 1/2 | EQM005SD | 25/4 | 80/13 | 2.28 - 6.04 | 6.04 - 12 | 800 | 1 | 0.54 | 146 | 2.4 |

| 1 | EQM010SD | 23/4 | 80/13 | 2.28 - 6.05 | 6.05 - 12 | 800 | 1.3 | 0.54 | 165 | 3.85 |